HOME > Technologies & Products > Laser Processing Systems > Ultra-High-Precision Drilling

Ultra-High-Precision Drilling

Ultra-high-precision drilling made possible using a beam rotator and galvano scanner manufactured in-house

Equipment external view

Strengths

■ Straight hole drilling

■ Fine drilling with excellent circularity, high degree of freedom

■ Round holes, square holes, holes with special shapes

■ Control over hole diameter, taper at the entry and exit sides

■ Processing position accuracy:<1μm

Target materials

Resin, Ceramic (Silicon nitride / Silicon carbide), Polyimide, SUS, Sapphire substrate, Artificial diamond

Equipment features

Control of the radius of rotation and the angle of incidence with a beam rotator enables a variety of hole shapes

Beam rotator manufactured in-house

Examples

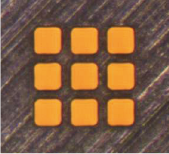

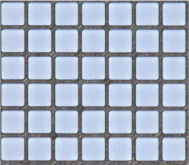

Small-hole drilling

Entry side

Silicon nitride

Thickness 0.25 mm

Hole dia. 20 μm

Pitch 26 μm

Machining speed 1.2 sec/hole

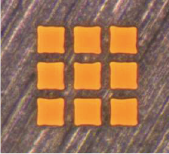

Exit side

Beam entrance

Silicon nitride

Thickness 0.25 mm

Square hole size 20 μm on a side

Pitch 28 μm

Machining speed 1.4 sec/hole

Beam exit

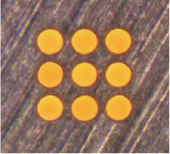

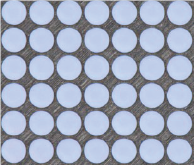

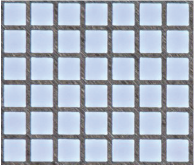

Narrow-pitch hole drilling

Entry side

Silicon nitride

Thickness 0.25 mm

Hole dia. 50 μm

Pitch / Wall 58 μm / 8 μm

Processing time 2.5 sec/hole

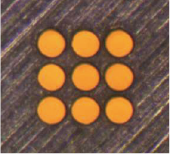

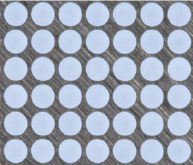

Exit side

Entry side

Silicon nitride

Thickness 0.25 mm

Square hole size 50 μm on a side

Pitch / Wall 62 μm / 12 μm

Machining speed 5.0 sec/hole

Exit side

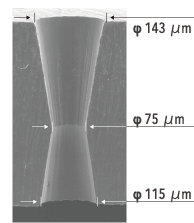

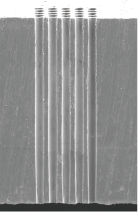

Straight hole drill machining

Cross Section

Super engineering plastic (LCP material)

Thickness 0.4 mm

Hole dia. 250 μm

Pitch 270 μm

Machining speed 3 sec/hole

Cross Section

Super engineering plastic (LCP material)

Hole dia. 15 μm

Pitch 27 μm

Machining speed 1.5 sec/hole

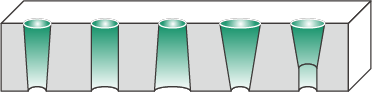

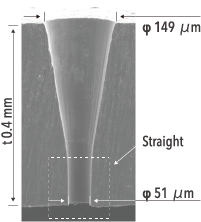

Special tapered hole machining

Cross Section

Cross Section